Spiral Pin, DIN7344, ISO8748, Spiral Pin Heavy Duty

Split spring pin, also known as cylindrical pin, is a headless hollow cylindrical body with axial slots and chamfers at both ends. It is used for positioning, connection, fixing, etc. between parts; it needs to have good elasticity and To resist shear forces, the outer diameter of these pins is slightly larger than the diameter of the mounting hole.

1. Elastic cylindrical pin

1) Lightweight spring pin

2) Heavy Duty Spring Pin

The main difference between light and heavy is the thickness of the material and the width of the chamfer. The thickness of the heavy spring pin material and the width of the chamfer are larger than those of the light.

2. Toothed Elastic Cylindrical Pin

1) Lightweight spring pin

2) Heavy Duty Spring Pin

The shape is similar to that of ordinary elastic cylindrical pins, the difference is that the axial grooves are staggered wave tooth shapes. .

3. Coiled elastic cylindrical pin

1) Lightweight Coiled Spring Pin

2) Heavy Duty Coiled Spring Pins

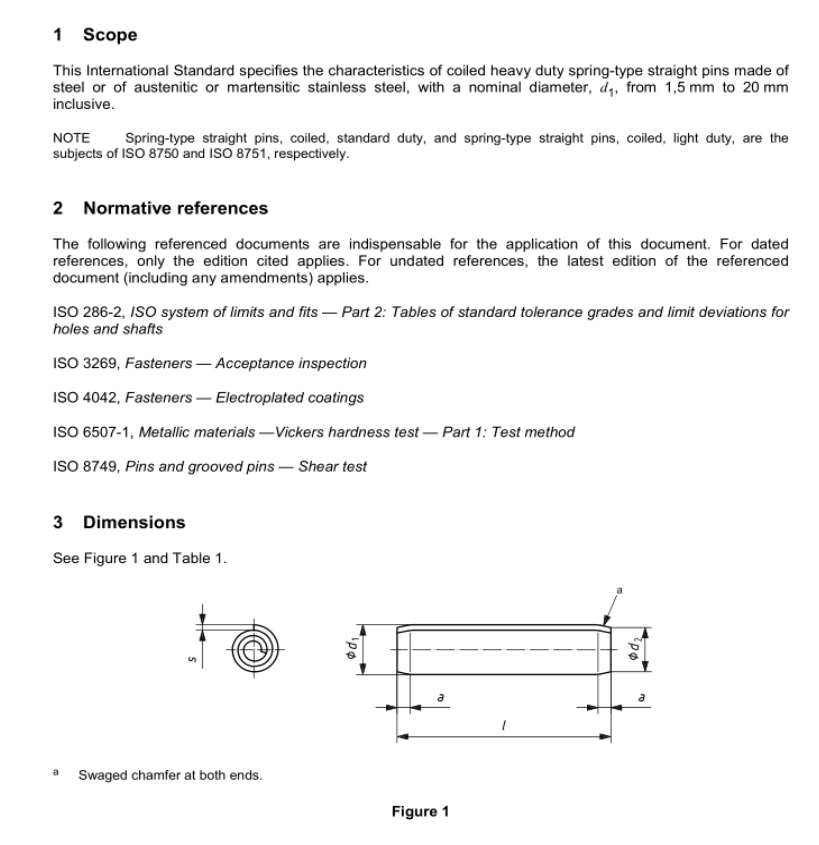

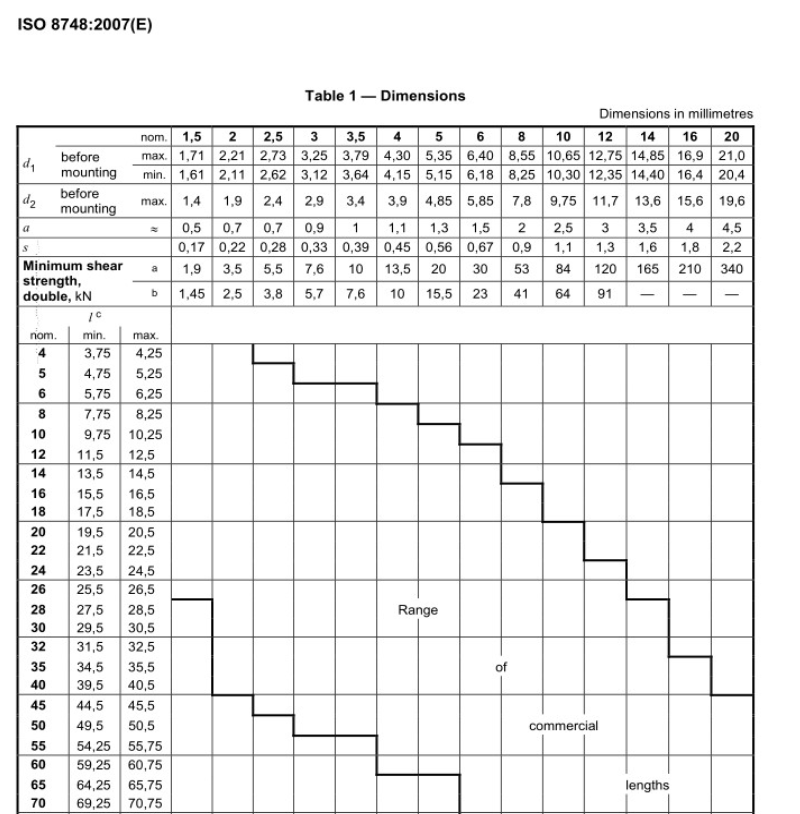

1 Scope

This International Standard specifies the characteristics of coiled heavy duty spring-type straight pins made of

steel or of austenitic or martensitic stainless steel, with a nominal diameter, d,, from 1,5 mm to 20 mm

inclusive.

NOTE Spring-type straight pins, coiled, standard duty, and spring-type straight pins, coiled, light duty, are the

subjects of ISO 8750 and ISO 8751, respectively.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document(including any amendments)applies.

ISO 286-2, ISO system of limits and fits-Part 2: Tables of standard tolerance grades and limit deviations for

holes and shafts

ISO 3269, Fasteners-Acceptance inspection

ISO 4042, Fasteners-Electroplated coatings

ISO 6507-1, Metallic materials-Vickers hardness test-Part 1: Test method

ISO 8749, Pins and grooved pins-Shear test

DIN7343 designs Coiled Spring Pins based on the concept of coil springs. The elasticity allows it to be pressed into the hole and remain elastic once installed. The elastic properties of the Coiled Elastic Pin can buffer vibration and shock, thereby avoiding damage to the hole on the component and maximizing the product life cycle.

DIN7346, ISO13337 light cotter pins. The main function is to fix the shift lever to the base. Once assembled, the pin has an ultimate load. Since the matrix material is plastic, a Coiled Spring Pin with a light load is the best solution, which meets the performance requirements and also meets the requirements for cost reduction.

Jiangxi Kaixu Automobile Fitting Co., Ltd, founded in 2017 (Original Ruian Kaili auto parts factory which was founded in 1999), located in Yihuang industrial zone,Yihuang county, Fuzhou city, Jiangxi Province Our mainly products are according to GB, ISO, DIN, AS, ANSI(IFI),BS, JIS, UNI standards and so on. And have major hundreds of categories of retaining rings, washers, keys, pins, bolts, nuts, screws. Meanwhile we also can produce some non-standard high quality products according to customer’s drawings or samples.

We have passed the IATF16949:2016 quality management system certification.

We insist on principles and business philosophy of “the Quality First” “Your satisfaction is our kaixu people’s pursuing goal “.