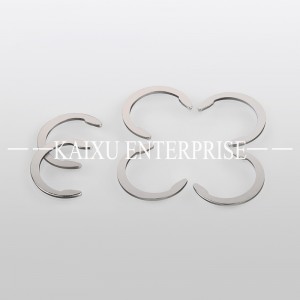

DIN 472 Retaining Rings for Bores Circlips for Holes Circlips External Circlips External Snap Rings fastener snap rings

Basic Internal Ring for Hole: A Strong and Durable Industrial Fastener

In the world of industrial fastening solutions, the basic internal ring stands out as a critical component, especially for applications requiring secure assembly in holes. These rings are designed to provide reliable retention, ensuring that parts stay in place under various operational conditions. Let’s explore the features, applications, and benefits of using basic internal rings in industrial settings.

What is a Basic Internal Ring?

A basic internal ring, often referred to as an internal circlip or snap ring, is a type of fastener that fits into a groove inside a bore or hole. It serves to hold components, such as shafts or bearings, in position, preventing axial movement. These rings are typically made from high-quality materials like carbon steel or stainless steel, which contribute to their strength and durability.

Key Features

1. Robust Design: Basic internal rings are engineered to withstand significant radial and axial loads. Their design allows for optimal distribution of stress, making them ideal for high-performance applications.

2. Corrosion Resistance: Many internal rings come with protective coatings or are made from stainless steel, providing excellent resistance to corrosion, particularly in harsh environments.

3. Ease of Installation: The installation of internal rings can be performed with standard tools, making them a convenient choice for assembly and maintenance. Their design facilitates quick installation and removal, reducing downtime during repairs.

4. Variety of Sizes: Basic internal rings are available in various sizes to accommodate different bore diameters and thicknesses, providing flexibility for diverse applications.